You Asked, We Answer: Why don’t you run more powerlines underground?

You often ask us why we don’t bury our lines—wouldn’t running them underground reduce the chance of power outages? It’s a great question, and we’re here to break down the answer for you.

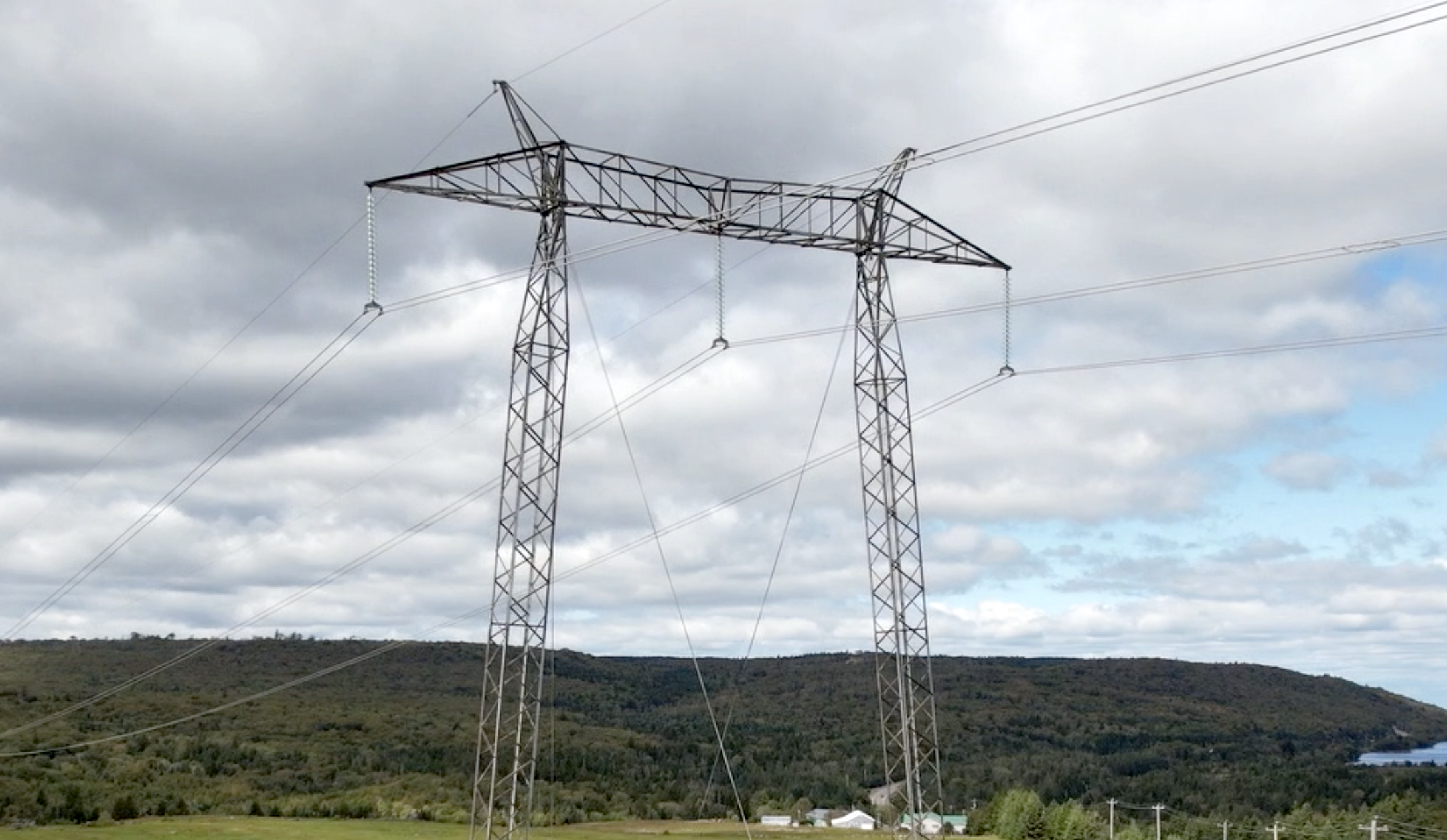

Nova Scotia’s rocky terrain

We have over 500,000 power poles and over 32,000 km of overhead powerlines in Nova Scotia—that’s the same distance as three round trips from Halifax to Vancouver. That’s a lot of powerlines that would need to be buried and require digging across most of Nova Scotia’s rocky terrain and throughout every neighbourhood in the province.

We currently have over 400 km of underground powerlines in urban centres and we’re always looking for ways to increase this amount when it makes sense to do so.

Underground powerlines do have reliability benefits, but they also have some challenges.

Photo: Underground lines are part of the Cogswell District project in Halifax.

Understanding the process

To bury our equipment underground—including powerlines, switches, transformers, and other electrical equipment—significant amount of digging, trenching, and construction is required. The equipment would need to be installed under roads, customer properties, and neighbourhoods across the province.

When sections of powerlines are buried underground, while the rest remains overhead, installing additional equipment on power poles is a necessary part of the process. This includes cable covers and concrete duct banks to connect underground services, protect customers, and ensure safety from any hazards.

Preventing outages: The pros and cons

It’s true that when it comes to underground systems maintenance costs and outage frequency can be lower. This is because underground systems are less susceptible to weather, damage from trees, and other external factors—but underground systems are not immune to failure.

Access to underground systems is very challenging. When something goes wrong with the underground system, it's much harder to locate the problem and even harder to get to it because our crews can’t immediately access the equipment. Sometimes, we may even need to tear up roads and yards to find the issue and fix it, making power outages more inconvenient, last much longer, and more costly to repair.

The lifespan of an underground line

Some underground equipment generally has a lower life span than overhead equipment, so it may require replacement sooner than overhead lines. This is due to the impact that our climate and geography have on our underground equipment—it needs to be able to withstand the impacts of being underwater. This means all underground electrical equipment must be safely designed and built to function underwater, as well as survive all other elements present in an underground environment, such as salt, soil, road debris, etc. This leads to equipment generally being more expensive to purchase and to install to ensure it can withstand those elements.

In areas where we have an underground system, like downtown Halifax, Dartmouth, and Sydney, we’re also competing with much more limited real estate than an overhead system. Under the city streets, there are already underground communications systems, like water, storm, sewage, and gas lines. If one of these systems had an issue, it can interfere with our equipment and potentially cause power outages. These other systems add many more complications to the construction, design, and maintenance of an underground power system—especially when we need to ensure it’s built safely and reliably.

Choosing the most cost-effective solution

As a regulated utility, we must find the most cost-efficient solutions for our customers. And there is a large cost difference between running powerlines overhead and running them underground. Installing powerlines underground instead of overhead can cost up to 10 times more.

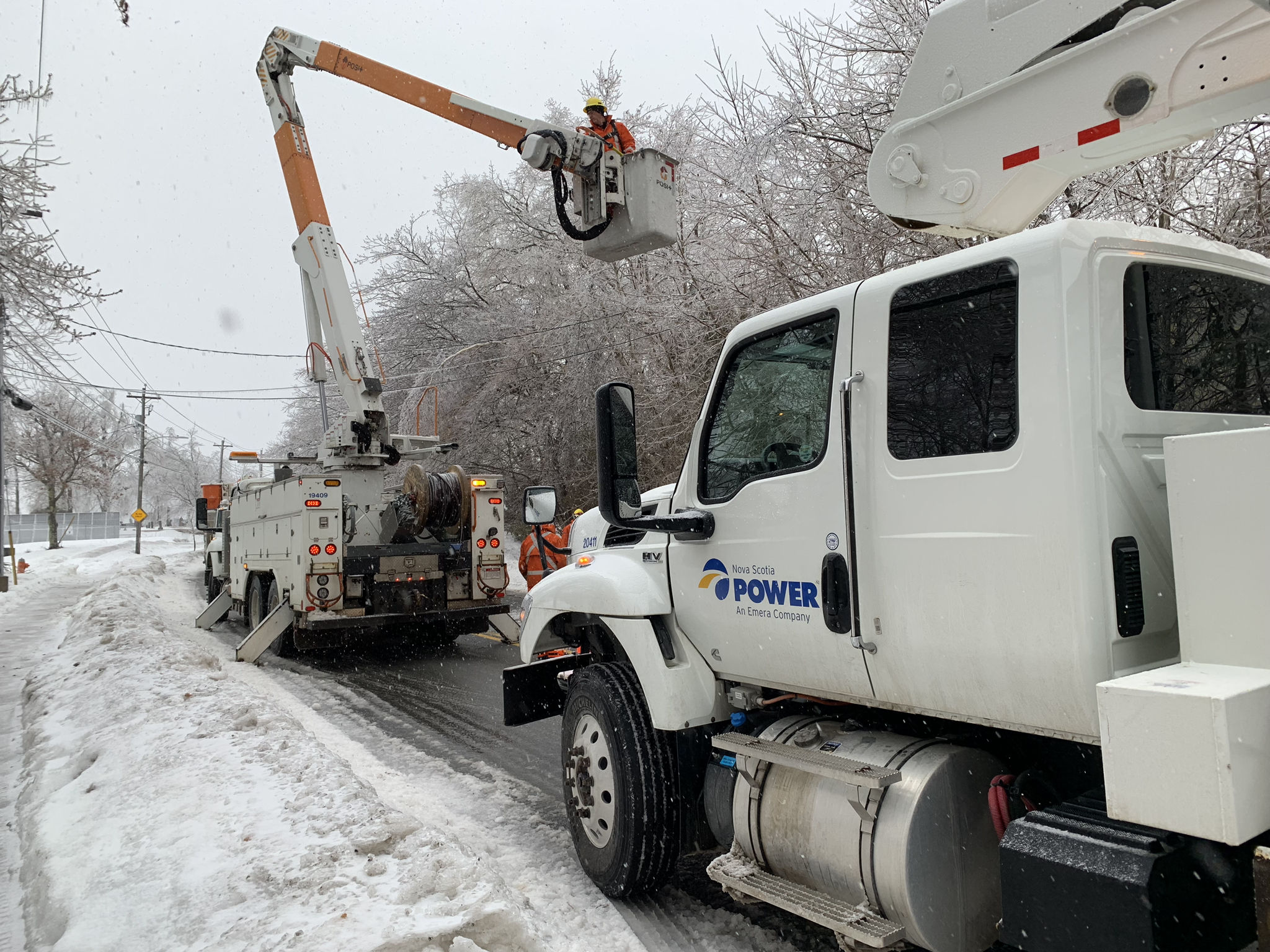

How we’re working to prevent power outages

Since there are reliability benefits to installing powerlines underground, we continue working with municipalities and developers to install underground systems when it makes sense and the impact on neighbourhoods and communities is minimal. We’re also focused on continuing to strengthen our electrical system.

We spend more than $100 million each year to protect our infrastructure and transmission and distribution network. This includes $20 million on tree trimming, large scale projects to upgrade electrical equipment, and installing new protective devices along our lines.

We’re using technology like ultrasonic scanning to help detect the high frequency sound given off when an insulator on one of our poles is breaking down. That way, we can replace it before it causes a power outage.

These are just a few examples of the work our teams do every day. We’ve also been testing innovative technologies, like batteries, to understand how they can provide reliable back-up power for customers during outages.

You can learn more about how we’re working to prevent outages on our

Reliability page.

Share This Post: