Electricity

Electricity

How We Make Electricity

We make electricity from a variety of sources. Our use of coal in generating electricity has declined significantly in recent years, thanks to the use of more wind power and natural gas.

Learn more about each type:

Coal

For many years, coal has supplied most of Nova Scotia’s electricity. Until 1999, our plants were supplied with coal mined in Nova Scotia, utilizing what was a local and economic resource. Most of the coal we use is sourced from international markets but we purchase domestic coal if it is available, meets environmental requirements, and is competitively priced.

Nova Scotia has the most aggressive greenhouse gas regulations in Canada, requiring a 25% reduction in emissions over the 2010 to 2020 period. The federal government has agreed to let Nova Scotia’s regulations take precedence over proposed national rules, provided that provincial rules achieve the same environmental benefit. This will save Nova Scotians hundreds of millions of dollars by allowing us to close coal units when it is most advantageous to our customers, not simply based on age, as the federal rules would have required.

| LINGAN GENERATING STATION | |

|---|---|

| Generating Capacity | 620 MW |

| Location | Lingan, Cape Breton Island |

|

| POINT ACONI GENERATING STATION | |

|---|---|

| Generating Capacity | 171 MW |

| Location | Point Aconi, Cape Breton Island |

Due to its design, Point Aconi is primarily fueled by petcoke, which is a solid by-product of the oil refining process.

|

| POINT TUPPER GENERATING STATION | |

|---|---|

| Generating Capacity | 154 MW |

| Location | Point Tupper, Cape Breton Island |

|

| TRENTON GENERATING STATION | |

|---|---|

| Generating Capacity | 307 MW |

| Location | Trenton, Nova Scotia |

|

Petcoke

We buy petcoke when doing so will save money for customers compared to other fossil fuels. It has higher carbon dioxide and sulphur dioxide emissions than coal, but lower mercury. We mostly use it at the Point Aconi generating station, which has special equipment that captures 90% of the sulphur.

| LINGAN GENERATING STATION | |

|---|---|

| Generating Capacity | 620 MW |

| Location | Lingan, Cape Breton Island |

|

| POINT ACONI GENERATING STATION | |

|---|---|

| Generating Capacity | 171 MW |

| Location | Point Aconi, Cape Breton Island |

Due to its design, Point Aconi is primarily fueled by petcoke, which is a solid by-product of the oil refining process.

|

| POINT TUPPER GENERATING STATION | |

|---|---|

| Generating Capacity | 154 MW |

| Location | Point Tupper, Cape Breton Island |

|

| TRENTON GENERATING STATION | |

|---|---|

| Generating Capacity | 307 MW |

| Location | Trenton, Nova Scotia |

|

Hydro

Nova Scotia has a 100-year history of using small hydro developments on our rivers to generate power. The first hydro plant was installed in 1903 by mining interests on the Liscomb River in Guysborough County.

We own and operate 33 hydroelectric plants on 17 hydro river systems across Nova Scotia, totaling 400 MW of generation capacity. Learn more about hydro & tidal power here.

Natural Gas

Natural gas is considered cleaner than other fossil fuels like coal and oil because it produces fewer air emissions. The Tufts Cove Generating Station in Dartmouth can burn oil or natural gas to generate electricity, but economical prices in recent years have led to it being run primarily with gas.

Because we’re producing so much electricity using natural gas at Tufts Cove, we’re making less power using coal at our plants, resulting in lower emissions and electricity costs.

The Tufts Cove Waste Heat Recovery project added a sixth generator to the plant in 2011 that produces up to 50 MW of electricity, enough to power up to 35,000 homes.

The new equipment captures waste heat from the exhaust streams of the two natural gas combustion turbines and uses it to power a new steam turbine and generator set, generating 25 MW of electricity without any additional fuel or emissions. A second 25 MW is generated by burning gas added directly into the waste heat stream from the turbines to increase energy output even further.

The Tufts Cove Waste Heat Recovery equipment captures waste heat from the exhaust streams of the two combustion turbines to power a new stream turbine and generator set.

| TUFTS COVE GENERATING STATION | |

|---|---|

| Generating Capacity | 500 MW |

| Location | Dartmouth, Nova Scotia |

|

Wind

Nova Scotia’s growth in renewable electricity has been largely through the development of wind power.

There are now more than 300 commercial wind turbines generating electricity in Nova Scotia, making our province a national leader in wind energy as a percentage of total generation capacity. Learn more about wind power here.

Biomass

Biomass is a renewable energy source used around the world. We operate a 60 megawatt biomass power plant in Port Hawkesbury, which supplies as much as 3% of the province’s electricity. It’s a facility that is helping us reach renewable energy requirements and provides a source of firm renewable energy that can back up intermittent wind generation. Plus, it’s a locally sourced fuel that helps displace imported coal.

Fuel Oil

Until the 1970s, most of Nova Scotia’s electricity was generated by burning oil. In the wake of the OPEC oil crisis, the government decided to switch from imported oil to Cape Breton coal as Nova Scotia’s primary source of electricity.

Today, oil supplies only a small amount of Nova Scotia’s electricity. The Tufts Cove Generating Station in Dartmouth is designed to burn either oil or natural gas, but due to price considerations in recent years has run primarily on gas.

We also operate three oil-fired combustion turbine units, located in Victoria Junction (66 MW), Tusket (24 MW) and Burnside, Dartmouth (132 MW). Because they burn expensive light fuel oil and tend to be less efficient than other thermal generating units, the turbines typically serve as a secondary source of generation and are not commonly used.

| COMBUSTION TURBINES | |

|---|---|

| Location and Generating Capacity | Burnside Combustion Turbine Generating capacity: 132 MW Location: Dartmouth, Nova Scotia Victoria Junction Combustion Turbine Generating capacity: 66 MW Location: Victoria Junction, Cape Breton Island Tusket Combustion Turbine Generating capacity: 24 MW Location: Tusket, Southwestern Nova Scotia |

| |

HOW WE DELIVER ELECTRICITY

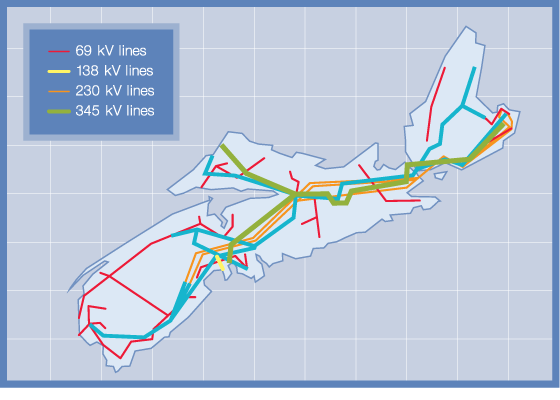

Nova Scotia’s transmission and distribution system consists of 31,800 kilometres of power lines stretching across roughly 29,500 transmission towers, 500,000 distribution poles, and 190 substations to bring electricity from power plants to customers.

Electricity carried by transmission lines is sent through distribution substations with transformers that convert the electricity down to a lower voltage level that is safe for delivery to homes and businesses. 26,500 kilometres of distribution lines then carry the electricity to localized areas and connect to individual meters on homes and businesses.

The Maritime Link is part of a larger strategy to address the growing demand for more renewable energy. It enables the transmission of clean, renewable and reliable hydro electricity from Newfoundland and Labrador to Nova Scotia and beyond.

A 350-megawatt capacity transmission line connects Nova Scotia with New Brunswick, enabling the import and export of electricity with neighbouring jurisdictions. The Nova Scotia system operator may import electricity when it is needed and can be purchased at a lower price than it can be generated inside the province, or may export electricity when it can be sold at a price that lowers costs for Nova Scotia Power customers.